Details

Product introduction:

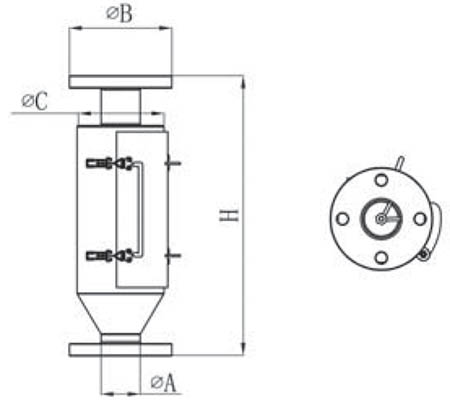

1. Type: Bullet Magnet Separator

2. Dimensions: Standard size of Customized

3. Material: NdFeB/Ferrite Magnet + SUS304/SUS316 Stainless Steel

4. Magnetic Action Range: As required

5. Max working temp.: 80 - 350 ℃

6. Surface treatment: Well polishing, Spray paint processing

Bullet magnet separator is designed for installation in pipelines or ducted systems, widely used in process of flour, grain, plastics granular, kaolin, french chalk and etc. Bullet magnet separator consists of a magnetic core with a conical tip design and a stainless-steel housing. The conical magnetic core ensure magnetic field optimum contact with the material flow.

Features of Bullet Magnet Separator:

1. The magnetic force can be chosen from 3000Gs to 15000Gs.

2. Design for quick and easy cleaning.

Advantages Of Bullet Magnet Separator:

1. Type: Bullet Magnet Separator

2. Dimensions: Standard size of Customized

3. Material: NdFeB/Ferrite Magnet + SUS304/SUS316 Stainless Steel

4. Magnetic Action Range: As required

5. Max working temp.: 80 - 350 ℃

6. Surface treatment: Well polishing, Spray paint processing

Bullet magnet separator is designed for installation in pipelines or ducted systems, widely used in process of flour, grain, plastics granular, kaolin, french chalk and etc. Bullet magnet separator consists of a magnetic core with a conical tip design and a stainless-steel housing. The conical magnetic core ensure magnetic field optimum contact with the material flow.

Features of Bullet Magnet Separator:

1. The magnetic force can be chosen from 3000Gs to 15000Gs.

2. Design for quick and easy cleaning.

Advantages Of Bullet Magnet Separator:

- Effective separator: this magnet separator will efficiently separates magnetic substances.

- Product purity: using magnet separator enhances product quality by removing magnetic impurities.

- Equipment protection: reduces damage to downstream machinery by using magnet separator

- Cost savings: lowers maintenance and product loss costs with magnet separator

- Customizable: tailored solutions for specific industry needs which is magnet separator

- Safety: magnet separator can enhances workplace safety by reducing hazards.

Importance Of Bullet Magnet Separator:

- Quality assurance: Magnet separator ensures product quality and purity by eliminating magnetic impurities.

- Operational reliability: magnet separator protects equipment, reducing the risk of breakdowns and ensuring consistent production.

- Safety enhancement: magnet separator minimizes workplace hazards associated with magnetic contaminants, promoting a safer work environment.

- Cost-effective operations: magnet separator helps in cost reduction, saving both on maintenance and product losses.

- Environmental responsibility: magnet separator contributes to eco-friendliness by reducing the environmental impact of magnetic waste.

- Tailored solutions: magnet separator provides customized options to meet specific industry requirements, optimizing performance.

Key Point Of Bullet Magnet Separator:

- Versatile magnetic separator for pipelines.

- Efficiently removes magnetic impurities using magnet separator

- Magnet separator is conical magnetic core enhances contact with material.

- Stainless-steel housing for durability.

- Magnet separator protects downstream equipment and improves product quality.

Specifications of Bullet Magnet Separator:

| Model | Dimensions (mm) | Net Weight (kg) | |||

| A | B | C | H | ||

| SC-RCYC-50 | 51 | 150 | 114 | 380 | 9 |

| SC-RCYC-76 | 76 | 185 | 168 | 540 | 20 |

| SC-RCYC-100 | 100 | 165 | 219 | 586 | 34 |

| SC-RCYC-150 | 150 | 225 | 273 | 655 | 48.5 |

| SC-RCYC-198 | 198 | 275 | 355 | 760 | 100 |

| SC-RCYC-248 | 248 | 325 | 426 | 850 | 121 |

| SC-RCYC-298 | 298 | 395 | 480 | 880 | 143 |

| SC-RCYC-395 | 395 | 480 | 610 | 1100 | 227 |

View more about Bullet Magnet Separator on main site